- HOME

- INSPECTION

INSPECTION SYSTEMS

From process to final quality

control.

You must be able to confidently verify the

quality of your product. Every time. So we promise to make your gages and inspection fixtures

simple, rugged, user friendly and repeatable. From start to finish, we maintain tight control of

every process to ensure the finished product is exactly what you asked for.

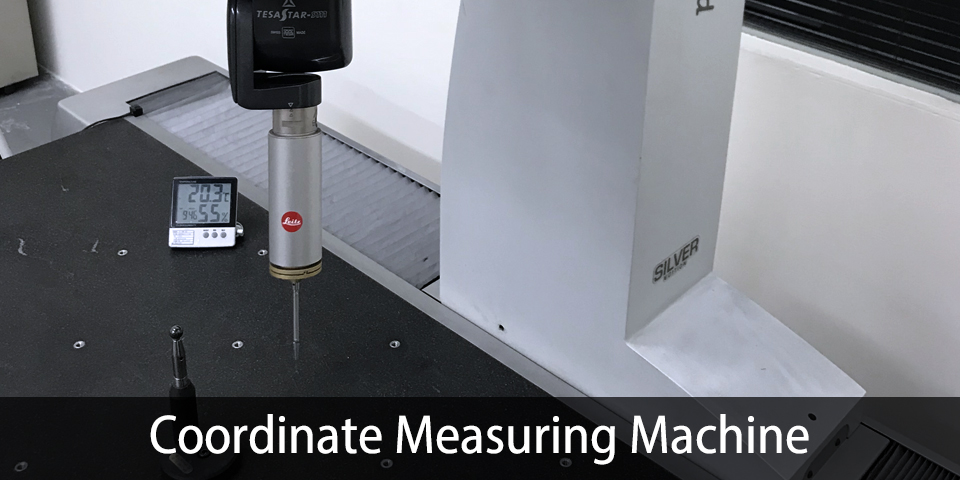

To ensure the final quality of

our work, the dimensional control of the workpiece is systematically done along with

the main steps, throughout its production. The samples are checked dimensionally

using CMM equipment. In order to speed up the approval with an immediate inspection,

COREGEN has the following equipment:

| Brand | Inspection equipment |

|---|---|

| B & S | Scanning CMM (700 * 1000 * 660) |

| B & S | Multi-function CMM (1500 * 3000 * 1000) |

| Haxagon | Probbing CMM (1200 * 2200 * 1000) |

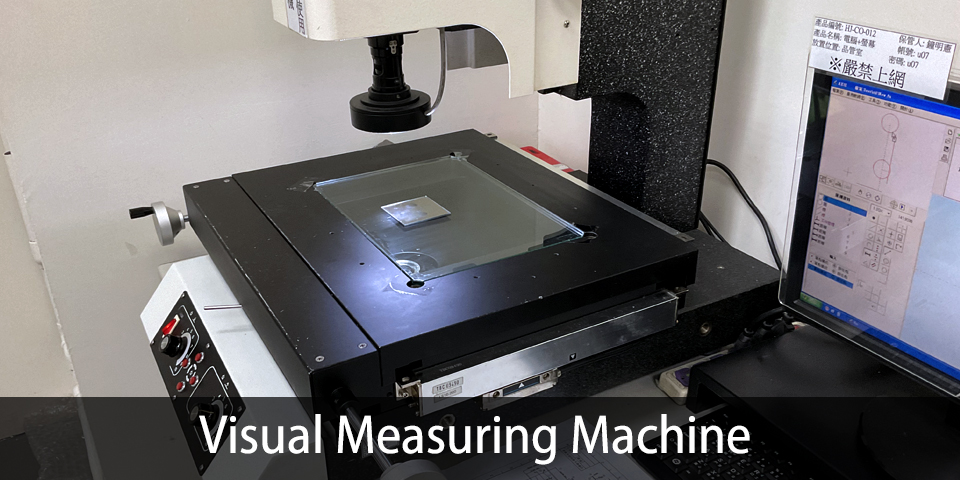

| Xiangen | Non-contact Measuring Instrument |

| Mitutoyo | 2D Height Gage |

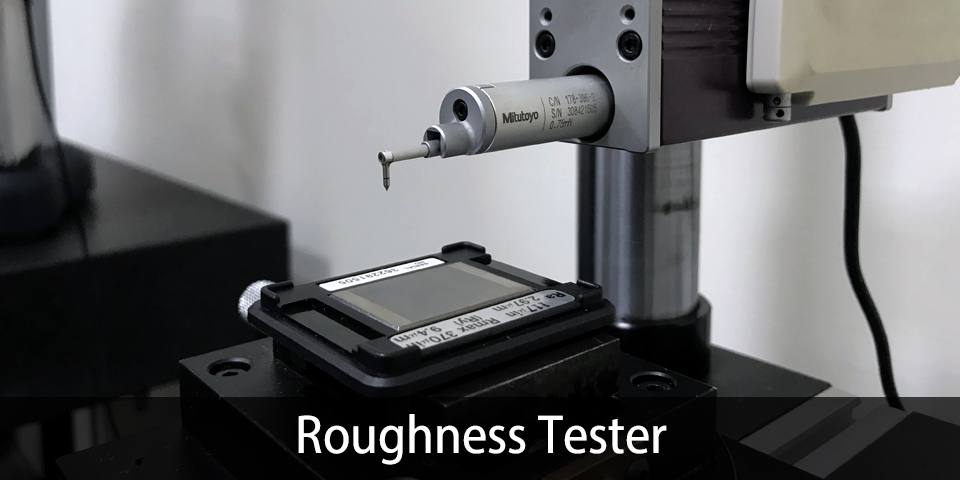

| Mitutoyo | Surface Roughness Tester |

| Mitutoyo | Outside Micrometer |

| Mitutoyo | Inside Micrometer |

| Mitutoyo | Screw Thread Micrometer |

| Mitutoyo | Bore Gage |

| Mitutoyo | Thread Gauge |

| Mitutoyo | Gauge Blocks |

| Mitutoyo | Three-point Internal Micrometer |

| Mitutoyo | Digimatic Caliper |

| Mitutoyo | Vernier Caliper |

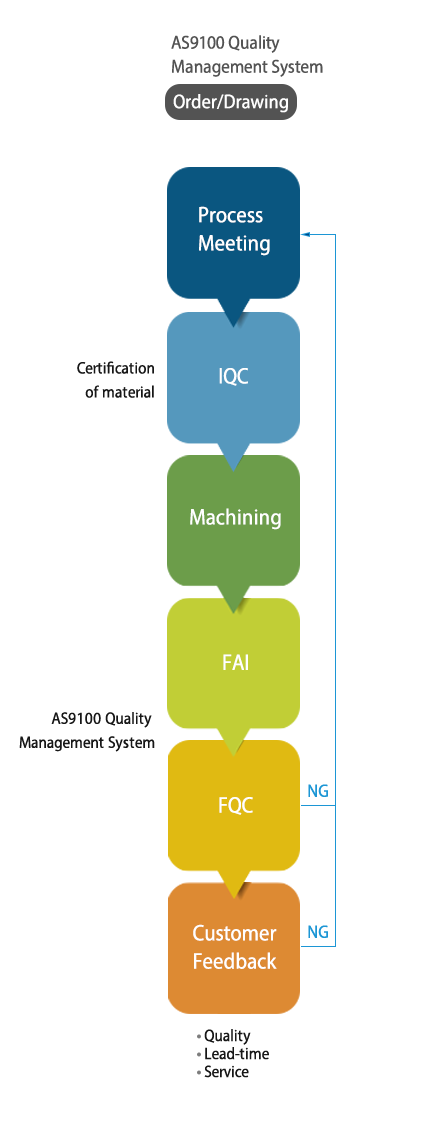

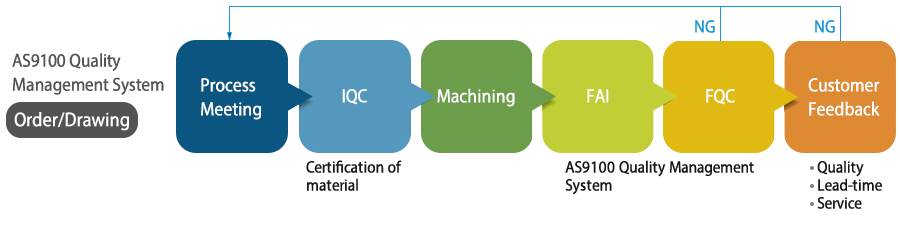

AS9100 Quality Management

System

The quality of product reflects the state of an

organization. COREGEN is always strictly obtaining the process of AS9100 and ISO

9001.

AS9100 Certification: To assure customer satisfaction, aerospace industry manufacturers must

produce world-class quality products at the lowest possible cost. This document

standardizes, to the greatest extent possible, the quality system requirements of the

aerospace industry. Standardization of compliance requirements results in cost savings due

to the elimination or reduction of unique requirements developed for each different

customer.

Quality Policy

1. Total Quality Management

2. Customer Satisfaction

3. Continuous Improvement

4. Planning for the Future

2. Customer Satisfaction

3. Continuous Improvement

4. Planning for the Future

Cybersecurity Policy

1. Total Quality Management

2. Customer Satisfaction

3. Continuous Improvement

4. Planning for the Future

Our company has implemented ISO 27001 and has established the following information security policies and objectives:

Implement information security management policies;

Fully implement information security management systems;

Train personnel in information security capabilities;

Strengthen the information security environment and information security response capabilities;

Achieve the measurable indicators of information security management policies.

2. Customer Satisfaction

3. Continuous Improvement

4. Planning for the Future

Our company has implemented ISO 27001 and has established the following information security policies and objectives:

Implement information security management policies;

Fully implement information security management systems;

Train personnel in information security capabilities;

Strengthen the information security environment and information security response capabilities;

Achieve the measurable indicators of information security management policies.